November 12, 2025

Industrial Roof Refurbishment: Continuity, Safety and Performance

Why refurbish an industrial roof today

Requests for industrial roof refurbishment typically arise from recurring needs: water infiltration issues, the installation of photovoltaic systems (often an opportunity to renew the entire building envelope), and asbestos management when the material’s condition requires intervention.

Working on existing buildings — often precast concrete structures — demands careful planning, strict safety standards, and constant coordination with the client to ensure operational continuity and avoid leaving any areas exposed during the works.

In response to the growing needs of our clients, we have expanded our services to include the refurbishment of industrial roofs on existing prefabricated buildings, integrating design, execution, and on-site coordination to deliver high-quality, fully restored roofing systems in full compliance with current regulations.

Our scope of work

What we do in the field of industrial roof retrofit

1. Roofing and waterproofing: tailor-made refurbishments for existing industrial buildings

Industrial Roof Refurbishment: Tightness, Durability and Long-Term Safety

Industrial roof refurbishment is a key intervention to ensure watertightness, durability, and long-term safety.

Seriana S.p.A. designs and installs custom roofing and waterproofing systems, tailoring every phase to the building’s characteristics, local weather conditions, and the client’s functional and aesthetic requirements.

Depending on the structural type and existing installations, we offer several roofing configurations:

• Metal roofs in steel or aluminium — ideal for mechanical strength, lightness, and long-lasting performance.

• Bituminous roofs, using high-performance membranes for superior waterproofing and weather protection.

• Polymeric roofs (TPO or liquid-applied systems) — recommended for buildings with complex layouts or low slopes, thanks to their flexibility and ease of application.

Each project is designed to restore full functionality to the roof, addressing issues such as leaks, material deterioration, or insufficient thermal insulation.

The goal is a long-lasting, watertight roof, resistant to snow, wind, and solar radiation — with a high-quality finish that enhances both performance and appearance.

Integrated design for complete performance

To ensure lasting reliability, every refurbishment project includes key technical factors that make the difference — both during installation and throughout the roof’s lifecycle:

• Structural and load verification: we assess consistency with the original load-bearing capacity and evaluate additional loads from snow, wind, or new roofing layers and photovoltaic systems.

• Thermal and energy performance: we verify the thermal transmittance (U-value) of roofs, walls, and skylights in compliance with Legislative Decree 311/2008 and according to the relevant climatic zone.

• PV-ready roofing: we prepare roofs for photovoltaic installation in compliance with B ROOF (EN 13501-5) fire classification, maintaining proper distances from skylights and REI-rated elements, and selecting non-penetrating fixing systems (clamps or pre-profiled seams).

Coordination with EPC and O&M contractors ensures future installation and maintenance without compromising waterproofing integrity.

This approach — combined with conscious material selection and controlled installation procedures — makes every roof refurbishment a reliable investment: fewer leaks, improved energy efficiency, photovoltaic readiness, and meticulously planned works that guarantee uninterrupted business operations.

2. Asbestos Removal: Safety, Compliance and Full-Cycle Management

Asbestos removal is a critical phase in the refurbishment of industrial roofs — essential both for protecting workers’ health and for ensuring compliance with current regulations (Legislative Decree 81/2008, Ministerial Decree 6/9/1994 and subsequent amendments).

Seriana S.p.A. manages every asbestos removal and disposal operation through an integrated and certified approach, providing clients with a complete, compliant, and safe service.

From preliminary inspections and material sampling to the preparation of work plans, containment systems, and removal procedures, we operate in partnership with licensed and authorized contractors in full accordance with legal requirements.

Each phase is carried out with the highest safety standards, applying controlled-risk proceduresand appropriate personal protective equipment (PPE) to safeguard both workers and the surrounding environment.

The process continues through to the final disposal of asbestos-containing materials at authorized landfills, with full traceability and documentation provided to the client upon completion.

Choosing an experienced and qualified partner is fundamental to ensure asbestos removal on industrial roofs is conducted safely, in strict compliance with regulations, and with timing coordinated to ongoing business activities — for a renewed, compliant, and risk-free roof system.

3. Skylight and Sheet Metal Refurbishment: Efficiency, Natural Light and Optimal Water Management

In industrial roof refurbishment, the proper management of natural light, safety, and rainwater drainage is essential to ensure the overall functionality and durability of the roofing system.

Seriana S.p.A. includes skylight replacement and sheet metal works as an integral part of complete roof renewal projects — improving comfort, efficiency, and safety in production environments.

We start with an analysis of natural lighting and an assessment of existing smoke and heat exhaust vents (EFCs).

Based on building requirements and regulatory standards, we design and install certified skylightsthat ensure uniform light diffusion, mechanical strength, and fire safety.

Water management: preventing overflow and infiltration

Extreme weather events require an engineering-based approach to roof hydraulics to prevent infiltration and structural damage.

Our design process focuses on eliminating the root causes of water accumulation rather than merely covering the symptoms, through:

• Sizing of gutters and downpipes for peak flow rates during heavy rainfall events (“cloudbursts”);

• Redesign of critical junctions (inlets, outlets, slope transitions);

• Anti-stagnation detailing and protection against capillary backflow effects.

Precision metalwork and finishing

Roof refurbishment continues with precision sheet metal fabrication and installation, designed for long-term performance:

• Gutters and downpipes engineered for extreme weather to prevent overflow and infiltration;

• Metal flashings, caps and claddings protecting critical points of the roof;

• Aesthetic and functional finishes ensuring uniformity, durability, and long-lasting protection.

The result is a more efficient, brighter, and safer roof system, capable of withstanding new climate challenges and integrating seamlessly with photovoltaic systems or ventilation equipment without compromising performance or waterproofing integrity.

Safety when working at height is a fundamental pillar of industrial roof refurbishment.

Seriana S.p.A. designs and installs lifelines, anchorage points, and fall-protection nets to ensure safe access, movement, and operations on roofs of any type.

Each system is custom-engineered based on the specific characteristics of the structure — including supports, stratigraphy, slopes, and access routes — and is fully compliant with Legislative Decree 81/2008 and the relevant UNI/EN standards.

Integrating safety devices from the design phase allows us to:

• Define safe routes for maintenance and inspection activities;

• Reduce operational risks and improve on-site safety management;

• Ensure full regulatory compliance and long-term maintainability.

The result is a safe and maintainable roof, equipped with certified lifelines and fall-protection systems, correctly positioned and fully compatible with other roof elements — such as skylights, photovoltaic panels, and sheet metal components — ensuring maximum safety, efficiency, and compliance during all future works at height.

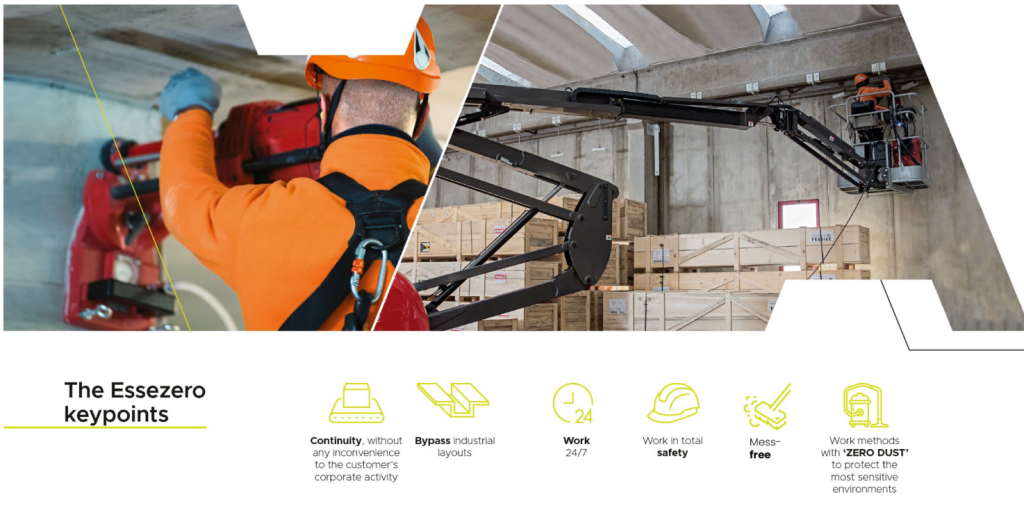

ESSEZERO Method: Working with Active Production

Since 2013, we have been operating on prefabricated industrial buildings using the ESSEZERO Method — our proprietary “zero-interference” approach designed to ensure operational continuity during structural works.

Activities are planned in 24-hour shifts (including nights and weekends), allowing for safe, clean, and dust-free operations, especially in sensitive environments, while bypassing industrial layouts to minimize disruption to production.

Working on an existing facility is inherently more complex than new construction: overhead systems, technical passages, dense layouts, and sensitive areas all require precise coordination.

With the ESSEZERO Method, we manage:

• Daily work fronts with controlled opening and closing phases — no roof area remains uncovered at the end of the shift;

• Flexible scheduling (including night and weekend shifts) to ensure zero interference with production lines;

• Constant communication with the client to report progress, manage critical points, and plan any minor shutdowns only when absolutely necessary.

The result: well-organized, traceable, and safe refurbishment projects that guarantee business continuity for our clients.

Why Choose Seriana

• Guaranteed operational continuity with the proprietary ESSEZERO Method;

• Engineering-driven approach integrating structural, safety, and energy considerations;

• Full regulatory compliance, including B ROOF (EN 13501-5), Legislative Decree 311/2008, Legislative Decree 81/2008, and UNI/EN standards;

• Complete asbestos management with full documentation traceability;

• Single point of contact for design, execution, and site coordination.

FAQ – Industrial Roof Refurbishment

Can a photovoltaic system be installed on the new roof?

Yes. We design PV-ready roofs, compliant with B ROOF (EN 13501-5) standards, maintaining safe distances and using non-penetrating fastening systems to preserve waterproofing integrity.

Do you manage asbestos removal as well?

Yes. We work with licensed contractors and authorized landfills, providing complete traceability of every phase.

Is production shutdown required during works?

In most cases, no. We plan all activities to avoid plant downtime. Any short interruptions are agreed upon in advance and limited to what is strictly necessary.

Would you like to refurbish your industrial roof without stopping production?

We perform a free preliminary technical assessment and propose the most suitable roof stratigraphy for durability, safety, and operational continuity.

Request information with no obligation about the renovation of your roof.

Are you interested in a roof retrofit for your company?

Leave us a message and a member of our team will get in touch with you shortly.